| RUS |

|

|

|||||||||

On 20 December 2018 the 6-m telescope began operating with the renovated mirror according to the observing schedule. Previously, the work on replacement of the primary mirror was prolonged first until 15 October and then until the actual completion of aluminum coating and measuring the characteristics of the primary mirror surface. The uncertainty of the due date was related with refinement of the mirror coating procedure and general deterioration in weather conditions in winter. The main stages of the work for the past period were:

(1) a series of seven test depositions to refine the modernized control system of the Vacuum Mirror Coating Unit;

(2) coating the mirror with aluminum;

(3) carrying out a series of observations to control the quality of the mirror surface after applying a reflective coating;

(4) adjusting the mirror support mechanisms and tilt of the mirror.

Test Depositions and Aluminum Coating

To apply a reflective coating on the mirror, a special Vacuum Mirror Coating Unit located in one of the rooms of the BTA dome is used. The BTA technical support team, directed by Grigory V. Yakopov, has for a long time been engaged in a progressive modernization of this instrument in order to improve the quality of the coating. A great amount of work has been completed in several years:

In 2018 the BTA technical support team had to refine the renovated instrument by selecting the control system parameters to prevent the formation of drops during evaporation of the material. Seven test depositions were carried out for this purpose. Each deposition included cleaning the chamber, installing the evaporator, pumping out, conducting the experiment, and evaluating the results; each cycle took several days.

The preparation of the Vacuum Mirror Coating Unit for the aluminum coating in 2018 was complicated by a long lack of funding, as a result of which the test works could not be started in advance, in summer, and we did not manage to invite the developers of the updated control system. Nevertheless, the BTA technical support team coped with the experiments independently and quite successfully.

After completing the series of tests, the mirror in the support cell was removed from the telescope, its surface was thoroughly cleaned, and the reflective coating was applied; then the support cell with the mirror was installed back on the telescope (Fig. 1).

The result of many years of work is the best ever reflecting coating on the BTA primary mirror in the history of SAO RAS.

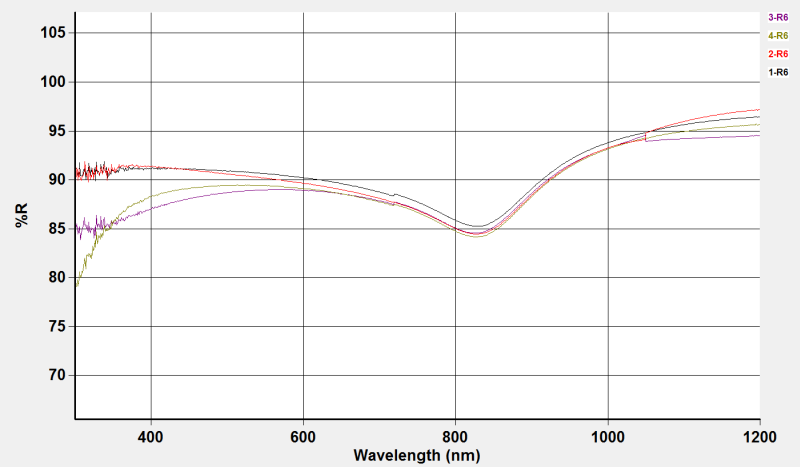

The witness samples (test samples placed inside the vacuum chamber

along with the primary mirror during aluminum coating) were examined

on the Cary-300 spectrophotometer at the Luch Scientific Production

Association (Podolsk, Moscow Oblast) in early December 2018.

Figure 2 shows the result. It is necessary to notice not only the

reflection coefficient that is close to the maximal but also the

reproducibility of the reflection curves of four witness samples

symmetrically located along the outer ring of the mirror. This result

indicates high uniformity of the coating over the entire area of the

primary mirror. The results are also confirmed by measurements on the

ST-7 reflectometer (SAO RAS, N.V. Borisov) in seven spectral

bands (Fig. 3).

Fig.2. The reflection coefficient of witness samples measured at the Luch Scientific Production Association.

Fig.3. The reflection coefficient measured with the ST-7 reflectometer (SAO RAS, N.V. Borisov). The dashed line is the maximal reflection coefficient (for aluminum), the points are the measurements.

Putting the Telescope into Operation for the Winter Period

On November 15, a series of observations was started to test the mirror surface characteristics after applying the reflective coating. No improvements were found compared to the results obtained in summer with the non-coated mirror. In general, there are three main problems.

To start observations with the telescope after aluminum coating, the following work was carried out in November-December.

(1) The outer edge of the mirror, which has the most significant surface deformations and makes the greatest contribution to scattered light, was diaphragmed.

(2) The mirror support mechanisms were set to the position "after the first iteration" (previously, five iterative adjustments were made in trying to correct the surface); this position allows the most significant improvement in the surface shape while the pressure on the mechanisms remains relatively small (additional stress up to 16 kg), simultaneously the effects of mirror imbalance are minimized (Fig. 5).

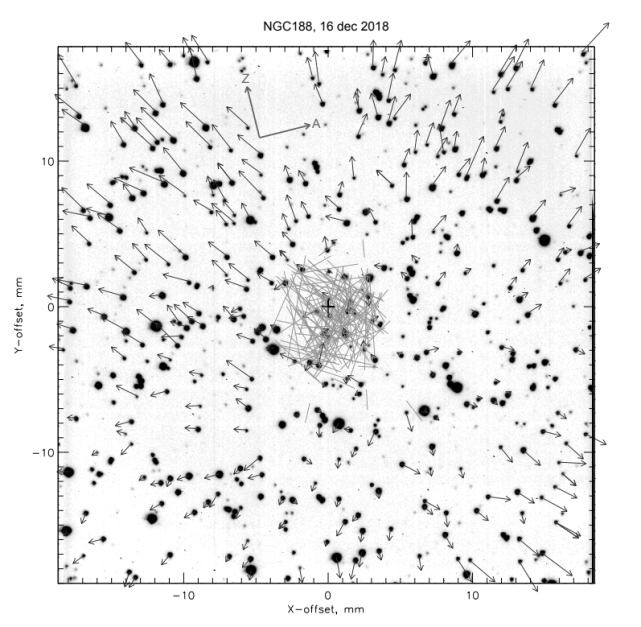

(3) The position of the aberration center was measured, and the mirror was tilted to match up the aberration center with the center the primary focus turntable. Then control measurements were taken (Fig. 6). Such an operation had already been carried out in summer with the non-coated mirror, but it turned out that the adjustment of the support mechanisms had led to a significant shift of the aberration center.

Fig. 6. Position of the aberration center (the directions marked by arrows) relative to the center of the primary focus turntable (the cross).

(4) The position of the light beam in the Nasmyth-2 focus was estimated (at the Main Stellar Spectrograph collimator). There is a shift of the beam from the collimator center of about 1 cm, however, accurate optical alignment of the N-2 layout is inexpedient at the moment.

(5) A series of observations (defocused star images, hartmannograms, measurements with a Shack-Hartmann sensor) was carried out to certify the mirror, and the telescope pointing model was calibrated.

Thus, the observatory has now successfully completed all the necessary procedures for installing the refurbished mirror and measuring the characteristics of its surface. At the same time, we have to state that the quality of the surface is unsatisfactory. The main reason for this is a considerable inhomogeneity of the glass of the mirror blank, which led to unaccounted effects in the so called "band control" during mirror repolishing, when the form of the surface was controlled with the mirror being supported by a special band, without a support cell, and all the related deformations were to be calculated and took into account for further operations. As a result of the inhomogeneity, significant deviations of the surface from the paraboloid appeared after installation in the standard support cell.

During winter and spring, the telescope will observe according to the schedule, the performance of the mirror will be checked in observations with scientific instruments. A commission was appointed to draw up a scientific and technical report on the primary mirror certification: D.O. Kudryavtsev (chairman), V.L. Afanasiev, N.V. Borisov, E.V. Emelyanov, Yu.M. Mametyev, M.V. Yushkin, G.V. Yakopov. Necessary documents should be prepared by 1 March 2019. The future of the renovated mirror is currently not determined, possible options are being discussed.

Dmitry O. Kudryavtsev, Deputy Director for Science, based on the data of the working group for primary mirror certification.

On May 18, the renovated primary mirror was transferred to the BTA cupola.

Before this event in the first half of May,

Under the supervision of two highly-experienced SAO staff members: the leading engineers of the BTA technical-support team (BTA TST) Yu.M. Mametiev and A.M. Pritychenko, the immensely complicated work on swapping the mirrors was conducted. The works began at 7 a.m. in order to use as much as possible the favorable "weather window" in a rainy season typical of this region. The former mirror that had worked at the telescope for 40 years was loaded to the container though the shutter of the cupola, then the refurbished one was transferred to the dome, put on the frame, and fitted into the centering sleeve. The whole procedure took us about nine hours. The mirror was installed at a specified position in the frame at the first attempt. The mirrors' weight is greater than 40 tons each; they were transferred using the crane with a lifting capacity of 100 tons able to move above the telescope cupola along the rail track. Most of the time was taken by lifting and installing extremely heavy glass mirrors at a specified position with maximum accuracy and safety. The replacement was "open", i.e., the mirrors were carried without containers which allowed us to save time needed for loading works.

The crane was once used in Lytkarino in 2007 before transportation of the mirror and after its arrival to the observatory in February this year; however, at that time the mirror should be lifted to a small height in order to take it from the vehicle platform. For reference, its transferral to the telescope dome, as well as the whole process of the mirror replacement itself, was last time performed in 1979. As distinguished from the past years, now the operator's cabin was equipped not only with the two-way communication but also with the video broadcast from the dome.

The following was told by Yury Yu. Balega, the SAO RAS scientific supervisor, the first vice-president of RAS, the former SAO RAS director from 1993 till 2015, and primary initiator and organizer of mirror reconstruction works: "In 2003, an idea has started up to replace the 6-m mirror for an 8-m one. In the workshop of the SCHOTT Company in Mainz (Germany), a cast workpiece, the copy of the VLT (Very Large Telescope) mirrors, was kept. I had several trips to Mainz for negotiations. The cost of works on the mirror replacement was six million euros. Besides the fact that the 8-m mirror is much bigger than the 6-m one, it also has a shorter focal length, thus, the whole BTA telescope should have been reconstructed.

In 2006 at a meeting, at which the participants besides me were: Yu.S. Osipov (the president of RAS), A.A. Boyarchuk (the member of the Academy of Sciences) and A.F. Andreev (the member of the Academy of Sciences and acting secretary of general physics and astronomy department of RAS), it was decided that the original BTA mirror should be repolished. In the federal budget of Russia, there was a separate line for a sum of 159 million rubles. The mirror was transported to the Lytkarino factory in 2007. Unfortunately, the budget was sequestered and the sum was reduced to 90 million rubles. Due to underfunding, the works at the Lytkarino Optical Glass Factory extended over 10 years. At the last stage of reconstruction, the Federal Agency for Scientific Organizations (FASO Russia) allocated money in two tranches by 50 million rubles to complete works.

The main problem about the primary mirror operating from 1979 was in the fact that the considerable part of its surface (about 40%) was damaged owing to numerous coatings with aluminum. These damaged areas of the mirror scattered the light rather than concentrated it in the focus. The quality of the original mirror installed on a telescope in 1975 and used until 1979 was extremely low due to the fact that during the figuring in the 1970s, a polishing machine made large dishings on it around bubbles that opened when forming a surface. The first four years of working with this mirror, we had to shield these areas with opaque dark screens. Then, in 1979, SAO received the second mirror.

It was decided at the factory to cut off the 8-mm upper layer of glass from the working surface of the mirror. This allowed them to remove the areas of large air bubbles. Then the process of shaping the "rotation parabola" and polishing began. The surface's shape was controlled in the workshop by means of a special interferometer. For this purpose, the mirror was placed in a vertical position, and the control was performed at the horizontal section of the optical path. The surface roughness of the mirror was raised to 15-20 nanometers. This corresponds to the surface quality of the best mirrors in the world. Although, the problem of the general shape of the mirror remains unsolved. It can be solved only after its installation on a telescope. For this purpose, the telescope with the renovated mirror will be guided to a point source of light - a star - and from the images obtained with the help of the Shack-Hartmann wavefront sensor, the deviation of the surface from the specified shape will be determined. The supporting mechanisms on which the mirror lies will be each time adjusted from these images. The process of adjusting and forming the mirror surface can take us several months.

The new mirror will provide reducing the scattered color background in images of stars and galaxies. For astronomers, this means an advantage in the limiting magnitude of the telescope by about 0.5-1 magnitude. Scientists will be able to look into the depths of the Universe at a distance of twice as much as with the old mirror."

The next stage of the work involves adjusting the supports of the mirror to a new weight (as a result of the mirror repolishing, it became lighter by 800 kilograms) and installing them in the specialized holes at the bottom of the mirror. The adjustment of supports is a very difficult task - it takes a whole working day to adjust three pieces, and there are sixty of them. The supporting mechanism is designed to support a part of weight of the primary mirror (1/60 of weight or about 700 kg). Each mechanism combines the axial and radial supports which transmit load to the mirror varying depending on the position of the telescope tube. Installation of supports is planned to be completed in the second half of June.

Photo: Philippova E.A., Sholukhova O.N., Oborina N.A.

On May 3, 2018, the final stage of the project of the mirror replacement at the 6-m BTA telescope - installation of the refurbished mirror - has started.

Let us recall that the intention to replace the mirror arose in 2004,

when it turned out that the quality of the operating mirror surface (used from 1979)

had gradually degraded from multiple applications of fresh reflective layers which

had been done every five years on average. At that time, it was decided to refurbish

the original mirror which had been used from 1975 to 1979, although, due to a number

of defects had been replaced and in storage for a long time in a specialized

container near the BTA cupola. Expert reviews have shown that with the use of

new instruments, the top layer of the mirror could be removed and the surface

could be repolished. Then the reconstructed original BTA mirror should not only

achieve the necessary performance but also can surpass the quality of the currently

working one. The works within the project started in 2007, when the mirror was

transported to the Lytkarino Optical Glass Factory

Despite the identity of the original and current mirrors and simplicity of the phrase "replacement of the mirror", the installation procedure is far from a simple swapping of one part for another due to its complexity. The works would require demounting the current mirror, its unloading and then loading the renovated mirror through the shutter of the BTA dome, recalibrating 60 mechanical mounting supports on which the mirror lies in the frame, putting the reflecting coating with the specialized vacuum instrument in the BTA dome, conducting high-accuracy measurements of the quality of the surface, and precise adjustment of the mirror and telescope, then realignment of its mechanical components, as the weight and focal length of the refurbished mirror has changed due to skimming. To a great extent, the fate of the whole project will depend on successful fulfillment of the above tasks, because despite calculations, numerous measurements, and control of the surface in the workshop at the factory, the final result can be seen only after the telescope is put into operation.

The works will continue throughout the summer. Main operations are performed by the BTA operation personnel with the involvement of specialists from the Lytkarino Optical Glass Factory. At the present time, the mounting supports are being deinstalled from the frame of the mirror. The unloading of the current mirror and loading of the renovated in the dome are planned for the second half of May; the exact date will be defined more precisely depending on progress of works and weather conditions.

Photo: deinstallation of the mounting support of the BTA primary mirror.

|